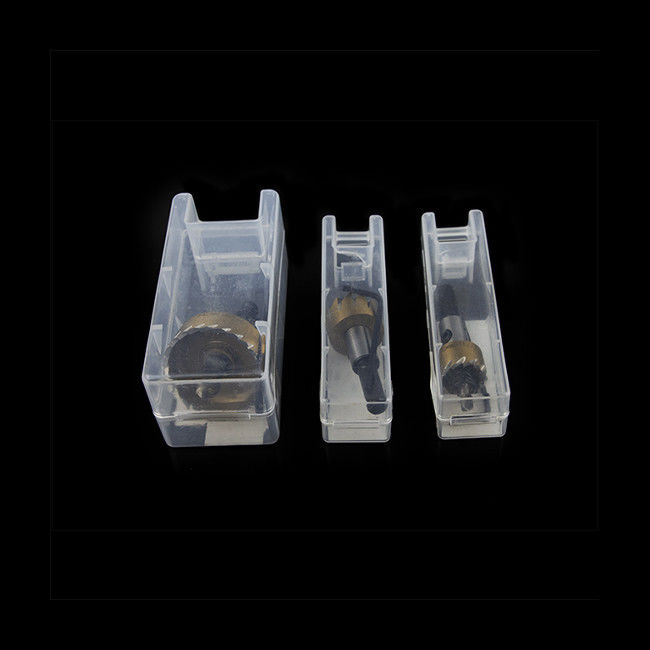

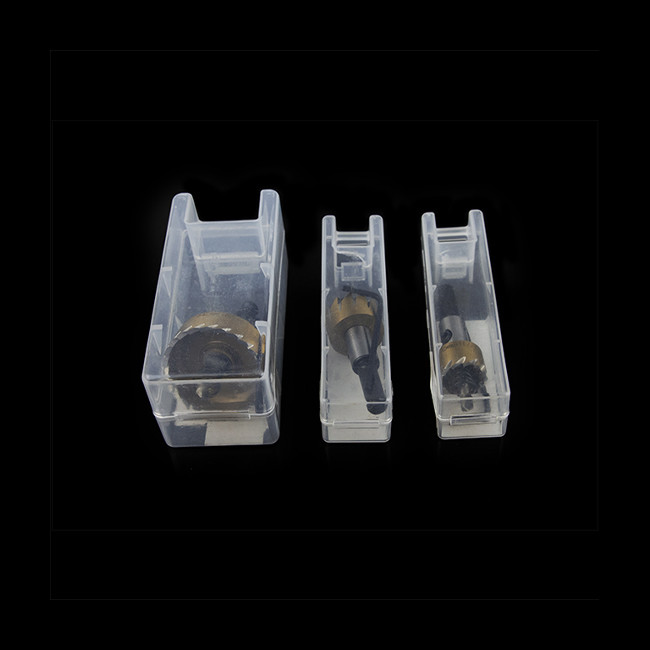

4241 Hss Hole Saw Cutter HSS Hole Saw For Stainless Steel Cutting

1. High Quality Material: Made from strong HHS high-speed-steel for durability, high hardness, fast cutting, impact resistance, wear high temperature

2. Sharp gears and anti-cutting with lower consumption make the product a long service life

3. Can be used for thick steel plates, cast iron, stainless steel, non-standard angle iron and other metal open hole. Perfect for installing locks, knobs on doors and cabinets, or drilling large diameter holes through desks, etc

4. Suitable for hand held electric drill, stand motor-driven drilling machine and mobile ribbon type magnetism drilling machine. Provide fast and precise cuts into stainless steel, sheet metal, cast iron, mild steel, aluminum, plastic,copper and brass

Company Profile

ZhongZuan(Chongqing)Precision Tool Manufacturing Co.,Ltd was founded in 1995 and has been specialized in researching and developing and producing the high-quality hole saw bits and drill bits of electric tools for 26 years. Factory is located in Chongqing, China and has an area of 11700 square meters with registered capital over RMB 5millions and over 120 employees. Our core products are diamond hole saw bits, HSS twist drill bits and alloy hole saw and drill bits, so far we have been cooperated with customers from over 10 countries in the world.

| product name: |

HSS hole saw |

| specification: |

12-100mm |

| Material: |

4341,6542 High speed steel |

| use: |

Suitable for opening holes on stainless steel, iron sheet, aluminum alloy and various pipes Suitable for hand drills and bench drills, easy to carry and decorate |

| specification |

Hole diameter |

Shank diameter |

Center drill diameter |

Total length |

| φ12 |

12mm |

7.8mm |

5mm |

66mm |

| φ13 |

13mm |

7.8mm |

5mm |

66mm |

| φ14 |

14mm |

7.8mm |

5mm |

66mm |

| φ15 |

15mm |

7.8mm |

5mm |

66mm |

| φ16 |

16mm |

7.8mm |

5mm |

66mm |

| φ17 |

17mm |

7.8mm |

5mm |

66mm |

| φ17.5 |

17.5mm |

7.8mm |

5mm |

66mm |

| φ18 |

18mm |

7.8mm |

5mm |

66mm |

| φ19 |

19mm |

7.8mm |

5mm |

66mm |

| φ19.5 |

19.5mm |

7.8mm |

5mm |

66mm |

| φ20 |

20mm |

7.8mm |

5mm |

66mm |

| φ20.5 |

20.5mm |

7.8mm |

5mm |

66mm |

| φ21 |

21mm |

7.8mm |

5mm |

66mm |

| φ21.5 |

21.5mm |

7.8mm |

5mm |

66mm |

| φ22 |

22mm |

7.8mm |

5mm |

66mm |

| φ22.5 |

22.5mm |

7.8mm |

5mm |

66mm |

| φ23 |

23mm |

7.8mm |

5mm |

66mm |

| φ24 |

24mm |

7.8mm |

5mm |

66mm |

| φ25 |

25mm |

7.8mm |

5mm |

66mm |

| φ25.5 |

25.5mm |

7.8mm |

5mm |

66mm |

| φ26 |

26mm |

7.8mm |

5mm |

66mm |

| φ27 |

27mm |

7.8mm |

5mm |

66mm |

| φ28 |

28mm |

7.8mm |

5mm |

66mm |

| φ30 |

30mm |

7.8mm |

5mm |

66mm |

| φ32 |

32mm |

7.8mm |

5mm |

66mm |

| φ35 |

35mm |

7.8mm |

5mm |

67mm |

| φ38 |

38mm |

7.8mm |

5mm |

67mm |

| φ40 |

40mm |

7.8mm |

5mm |

67mm |

| φ42 |

42mm |

7.8mm |

5mm |

70mm |

| φ45 |

45mm |

7.8mm |

5mm |

70mm |

| φ50 |

50mm |

7.8mm |

5mm |

70mm |

| φ53 |

53mm |

7.8mm |

5mm |

70mm |

| φ55 |

55mm |

7.8mm |

5mm |

70mm |

| φ60 |

60mm |

7.8mm |

5mm |

70mm |

| φ65 |

65mm |

7.8mm |

5mm |

70mm |

| φ70 |

70mm |

7.8mm |

5mm |

70mm |

| φ75 |

75mm |

7.8mm |

5mm |

70mm |

| φ80 |

80mm |

7.8mm |

5mm |

70mm |

Feature

1. When drilling, the center drill penetrates the material to be processed first, as the axis, the drilling is more stable.

2. Special blade tooth grinding technology and high-strength substrate, strong perforation ability, prevent chattering, and improve drilling ability.

3. Triangular shank design, effectively prevent slipping in the process of drilling, strong torque resistance.

4. When the center drill becomes blunt, the center drill can be replaced and used.

Note: Pay attention to the temperature when cutting cold and hard materials. If it is too high, add water. Please use it step by step when drilling, and do not use excessive force.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!